Silicone Handle

Silicone rubber is combined with different material parts to produce various styles of handles according to the function of silicone products. The length of the Jan Huei customized handle is about 100mm to 300mm, and the largest size we can customize is about 400mm. Silicone has elasticity, which can not only reduce the discomfort of lifting but also increase the strength of the handle. Through a special production method, we can enclose soft or hard materials in the silicon handle, which is why Jan Huei has won the trust of customers.

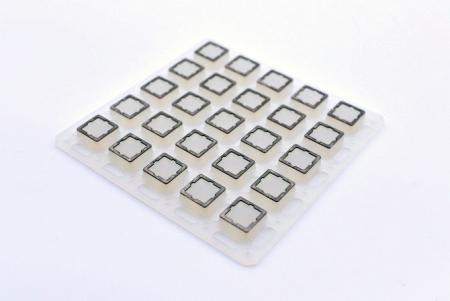

A common style of handle is silicone combined with a plastic buckle or plastic strips. It is used for suitcases, briefcases and luggage, and so on. Another style of handle is silicone combined with metal, which is used for industrial cases or electronics applications. To avoid user burn by a metal handle, silicone combined with metal, can prevent heating by a metal handle. Compression molding or injection molding can form the handle. In this example, we use compression molding. Whatever both molding, the key point in the molding process is that the metal is without damage, and the silicone is tightly bonded to the metal.

Key Features and Benefits

- The texture is flexible, reducing the feeling of discomfort.

- Silicone rubber combined with different materials to enhance the strength of the handle.

- Insulate high temperature and protect hands.

Specification

- Molding: Silicone Compression Molding, Silicone Injection Molding

- Size: Maximum Size 400mm

- Color: Customized

- Material: Silicone

- Effective Cases

- Related Products

Silicone Rubber Combined with Metal

Silicone rubber combined with metals such as steel, aluminum, brass, and other metals can strong structures for silicone products. Some kinds of customers have specific protective requirements like increasing the strength of silicone pads to keep inside electronic products safe. For example, a crash pad uses silicone to protect the parts from impact damage, metal parts can avoid deformation. Our products with silicone metal bonding are heat and UV-resistant.