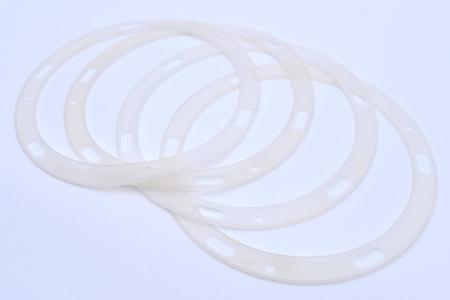

Silicone Rubber Seal

Grommet, Gasket, O-ring

Silicone rubber seals can be customized in any shape to meet customers' specific needs. The application of silicone seal is wide, we can see seal range from precision parts to industrial machines. You can place the silicone seal in the grooves or gaps of the mechanical equipment to fit on the surface of the mechanical equipment to achieve airtightness and prevent wear. We can provide many styles of silicone seals, such as O-rings, X-rings, Y-rings, C-rings, V-rings, and star-shaped seals with colors, hardness, and so on. They are all resistant to extreme temperatures, UV, and ozone exposure.

Silicone seal and gasket are usually as waterproof parts, leakproof oil, dust proof, etc. Jan Huei could customize sizes of seals from 10mm to 400mm in diameter. According to demand, we could provide proper suggestions to customers. In our experience, we have been manufacturing silicone, Viton, NR, and NBR for sealing.

Specification

- Molding: Silicone Compression Molding

- Size: Maximum Size 400mm

- Color: Customized

- Material: Silicone

- Hardness: Shore A 30 ~ 70

- Effective Cases

- Related Products

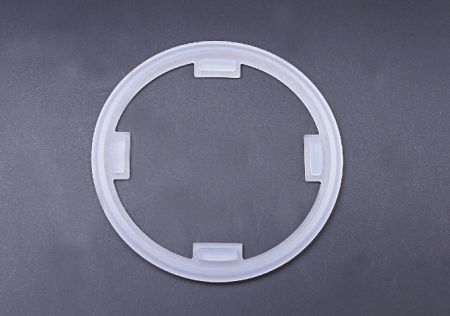

Silicone Combined with Glass

The silicone seal applied to the glass panel can add a waterproof function to it. The silicone rubber is combined with the glass panel tightly by inserting molding. It could achieve the anti-dust and waterproof effect. Jan Huei is an expert on LSR molding technology to produce silicone seals. Considering the type of production, as the same structure, LSR injection molding could enhance production yield by 50-80% more than compression molding. It also could save assembly costs and increase production capacity. Therefore, most customers start to choose this kind of production way to produce a waterproof product.